Guidelines

1. Welding

For pipe work inside buildings

- No pipe should be secured to another pipe or used as a support for other pipes.

- The arrangement of pipes should facilitate their identification. Mounting plates should be used where required.

- Pipes should be laid so as to prevent the formation of air locks. Where pipes are likely to suffer from frost damage,drainage fittings should be provided at the lowest points of the system.

- Where pipes are laid above one another, exposed cold water pipes should be on the lowest level in order to minimize the risk of condensation.

- Where a system provides water to two or more buildings, a riser should be installed in each building.

- Where draw-off points on a storey require backflow prevention but are not individually isolated (DIN 1988 part 4), the main branch pipe should branch off from the riser not less than 300 mm above the maximum possible water level on the storey.

Instructions for Welding of RAKtherm Pipes & Fittings

The welding machine is heated up to 260 °C (described in “Using RAKtherm Welding Device & Tools”).

1 Use RAKtherm pipe cutter to cut the pipe. Make sure that a straight and clean pipe end results and not at a skewed angle. This is to ensure that the welding adheres to the right conditions.

The joining process during RAKtherm fusion welding can be divided into three stages:

Stage I: Initial heating and fitting expansion.

Stage II: Heat soaking to create the joint.

Stage Ill: Joint cooling.

Firstly, pipe ends must have properly finished squared ends as opposed to having a chamfered or broken edge. This ensures that the central cold zones come in full contact with the welding tools and proper heat conduction will accordingly be achieved. Before welding Stabi composite pipes peel-off the aluminum polypropylene layer completely.

• Secondly, the pipe surfaces to be joined must be properly cleaned to remove contaminants and foreign material. Otherwise, any contamination on the pipe surface is retained at the joint interface, which can significantly reduce the strength of the joint.

• Finally, the pipe and fitting should be clamped during welding to eliminate relative movement. This ensures that the molten polymer is allowed to fuse fully at the fusion interface, developing a strong joint.

2. Mark the welding depth with a pencil and measurement plate which are provided with the RAKtherm welding kit.

3. Enter the end of the pipe into the tool up to the marked depth without twisting it and simultaneously and also without twisting, push the fitting onto the heating tool, observing the general guidelines for heating up times outlined in table 4.1.

Timing for heating should not start until the pipe and fitting reaches to the marked welding depth. Both fitting and pipe should be heated for a set time, known as the heating time. When heating time is complete, the pipe and fitting should be removed from the heating tool, and pressed together to the marked welding depth for a few seconds without twisting a homogeneous structure of the same material is thereupon formed. The major alignment should be done before insertion of the pipe and fitting.

Use fusion time for minor alignment before fusion is complete and the assembled parts have cooled. Never mechanically stress the welding joint before cooling time. A cross-section of a properly welded RAKtherm joint will normally show a smooth transition between the two initial parts. This is because the components have uniformly melted and fused into each other to form one single piece. RAKtherm Electro Fusion coupling welding procedure please see in Technical Manual Installation.

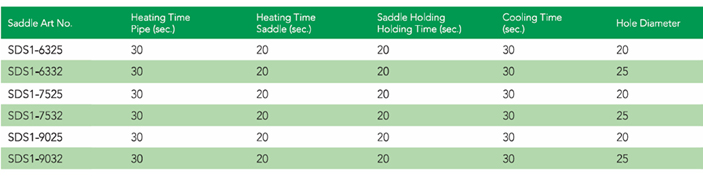

INSTALLATION & INSTRUCTION FOR THE WELDING SADDLES

Use of RAKtherm welding saddles:

• Subsequent extension of existing pipe systems.

• Alternative use to tees, especially in maintenance and alteration jobs.

• Direct branching of a service line to a supply line Preparation for welding Mount the RAKtherm saddle welding tool to the welding machine. Once the tool is positioned, check that the surface temperature is in the range of 260 degree C (described in “Using RAKtherm welding Device & Tools”). Make sure that the surface to be welded is clean and dry.

Drill out the pipe at the welding point with a spiral drill bit. If necessary, clean the hole from any burrs. Caution is to be taken in drilling the correct depth and diameter see below. When drilling, make sure that the opposite pipe wall is not reached, otherwise, the pipe will be damaged

After drilling, remove the remaining aluminum at the entrance of the hole with a chamfering device. Heat up the pipe with the tool for 30 seconds. Subsequently, heat the saddle along with the external surface of the pipe for another 20 seconds, total of 50 sec for the pipe. Make a light pressure with the saddle on the tools. Make sure that the entire surface is in contact with the heating tool. After finishing the heating phase, remove the welding unit and insert the welding saddle nozzle into the heated drilled pipe hole. Fix under light pressure, avoiding rotation for an additional 30 sec.

For RAKtherm Stabi pipe The system may be exposed to full load after 15 minutes of welding.

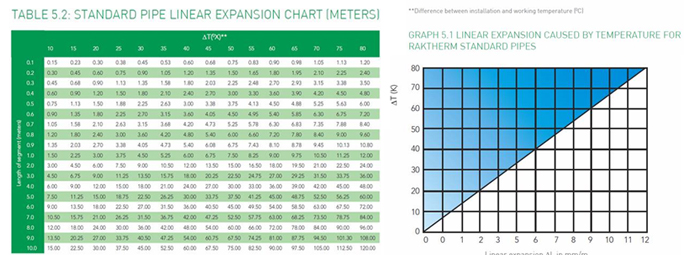

2. Linear Expansion

Linear expansion of pipes is directly proportional to the heat subjected to the pipe material. Hence, cold water pipes have practically no linear expansion and could be neglected in the installation design.

On the other hand, expansion of pipes is significant in warm water and heating installations and in extreme temperature varying environments, and therefore needs to be considered. Formula for Calculation of Linear Expansion

The linear expansion ∆L is calculated according to following formula:

∆L=α• L•∆T

Where: ∆L Expanded length (mm)

α Coefficient of linear expansion (mm/mK)

L Length of segment in (mm)

∆L Temperature difference between working and installation Linear Expansion Calculation

Example: Assuming you need to calculate the expansion (∆L) of a standard RAKtherm pipe segment

(L) of 1.6 meters at a maximum working temperature of 70°C.

You know that the RAKtherm standard pipe has a coefficient of linear expansion of (α = 0.15).

You know that the installation was executed at the typical ambient temperature of 25°C.

∆L =α•L •∆L or ∆L = 0.15 *1.6 *(70°C -25°C) =10.8 mm

That means you can expect a linear expansion of 10.8 mm for this segment of pipe if the temperature difference is respected. Alternatively, you can quickly obtain the result from the following table for different types of pipe:

3. RAKtherm Pressure Test

RAKTHERM PRESSURE TEST

RAKtherm pipes due to their material properties expand when subject to pressure, which influences the test result, this may also be affected by differences in temperature of pipe and test medium resulting from a high thermal expansion coefficient of the pipe material, a change of 0.5 to 1 bar. Thus, the test medium should be kept at constant temperature throughout the test acc to DIN 1988 TRWI the pressure test must be performed 1.5 times of the operating pressure. Using cold water, the pipe system should be filled slowly and bled completely using calibrated measuring instruments that indicate pressure changes of 0.1 bar wherever possible. Measurements should be taken at the lowest point of the pipe system.

Where pipes and fittings have been welded, the pressure test should not be performed before two hours have elapsed after the last welding operation. The pressure test consists of two stages: For the first stage, a test pressure equal to the permissible working pressure plus 5 bar should be applied twice within 30 minutes at 10 minute intervals. Then the pressure should be checked. In case more than a 0.6 bar drop occurs over a period of 30 minutes at a rate of 0.1 bar/min, then a leakage is reported. The second stage should follow the first stage without interval and should last minimum of 2 hours. Then the Pressure drop should be checked. If the pressure drop is more than 0.2 bar and the pipe work shows signs of leakage, then the network should be corrected and the test must be repeated.

4. Standards & Regulations

Standards & Regulations

RAKtherm Pipes and fittings are produced with the following standards and regulations:| DIN 1988 DVGW Code of Practice (Drinking water supply systems; materials, components, appliances, design and installation). |

| DIN 8076 Standard for testing metal threaded joints. |

| DIN 8077 Polypropylene (PP) pipe dimensions. |

| DIN 8078 Polypropylene (PP) pipes; general quality requirements testing & chemical resistance of pipes and fittings. |

| DIN 2999 Standards for fittings with threaded metallic inserts. |

| DIN 169621Ptl Pipe joint assemblies and fittings for type 1 & 2 polypropylene (PP) pressure pipes; bends produced by segment inserts for buff welding dimensions. |

| DIN 16928 Installation, pipe and fitting connections. |

| DIN 4109 Noise control in buildings. |

| DIN 4140 Insulation of service installations. |

| DVS 2207 Welding of thermoplastic pipes and fittings. |

| DVS 2208 Welding machines & devices for thermoplastic pipes and fittings. |

| BS 6920 Suitability of non-metallic products for use in contact with water in tended for human consumption with regard to their effect on the quality of the water. |

| DIN 16836 Multilayer Pipes-General Requirement and Testing DVGW W544 General Requirements and Testing of plastic pipes ISO 9001 -2008 Quality Management system. |

| OHSAS 1 8001 British standard for Health and safety management system |

5. Transport & Storage

TRANSPORT STORAGE

During transportation and storage, RAKtherm piping system components could be exposed to open air at any temperature for short period of time provided that it is kept in the shade protected from direct sunlight. However, at temperature below 0°C, the material becomes more susceptible to damage if hard blows are delivered. Hence, at low temperature, the material has to be treated with more caution. It is not recommended that RAKtherm pipes and fitting be stored in open air for long period of time.

Additionally, a solid base is recommended to avoid any deformation of pipes during transportation and storage. Even though RAKtherm pipes are extremely robust it is recommended to treat the material with care.